-

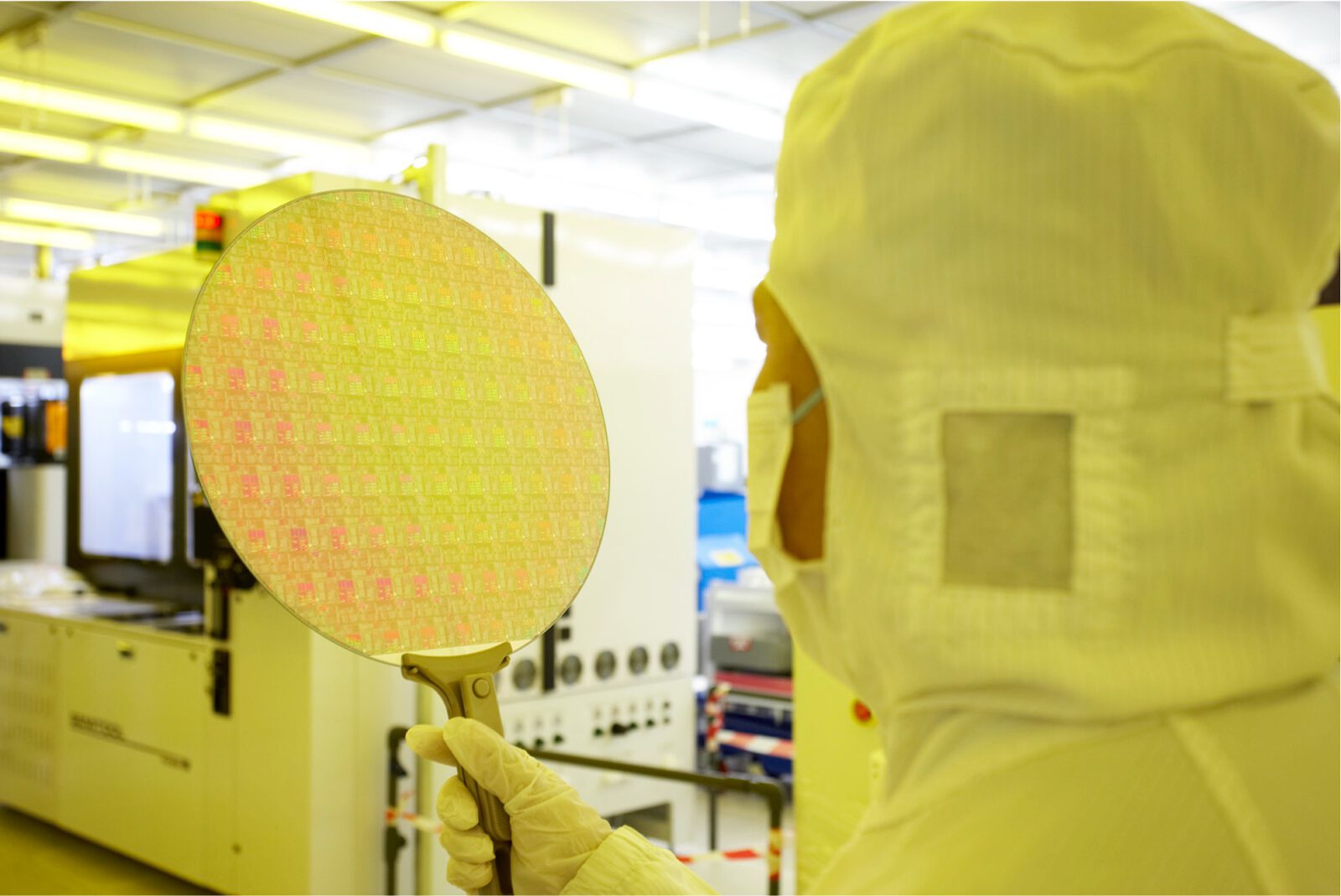

State-of-the-art Class 10/100 cleanroom and lab space

-

8” / 12” silicon and 12″ glass wafer processing

-

Supports R&D, single/multi process run, prototyping to small volume fabrication with automated industry-ready tools

-

Full suite of fabrication tools

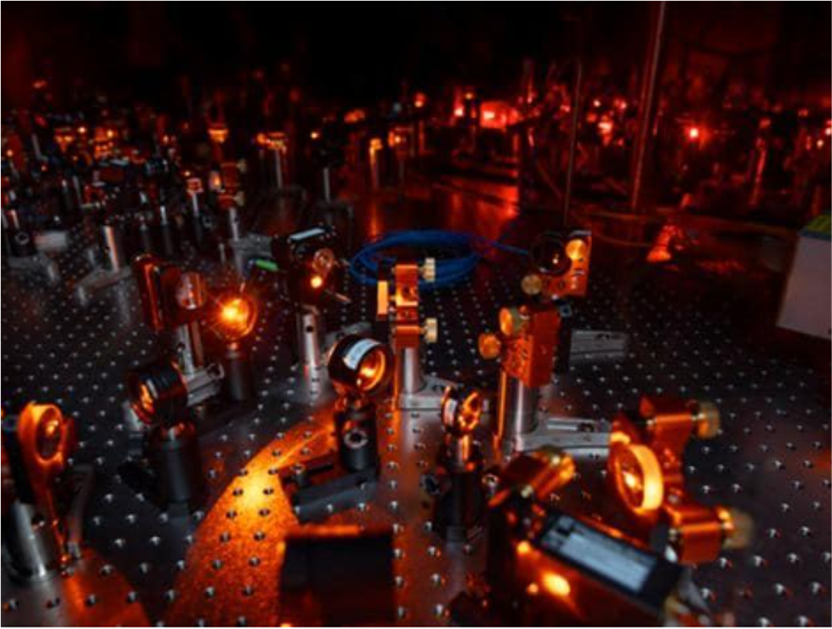

Lithography

- ArF immersion scanner (>45 nm L/S)

- KrF scanner (>110nm L/S)

- GHI-line stepper (>0.8μm L/S)

Dry Etch/Dry Strip

- Si/SiOx/a-Si high aspect ratio etch (up to 1:10)

- SiN, III-V, Lithium Niobate etch

- N2, O2, forming gas strip

- Descum

Wet Etch/Cleans

- Bench and single wafer frontside and backside particle cleans

- Post-etch residue removal and PR strip

- Cu, Ti, Si, oxide wet etch

Thin Films

- PVD sputtering: Ti, TiN, Ta, TaN, Cu, Al, Ni, AlN, ScAlN, SiN

- PVD evaporation: Au, Ti, Al, Ni, Cr

- PECVD: Low-stress TEOS, SiOx, SiN, a-Si

- ALD: TiN, HfOx, AlN, Al2O3, TiO2

Diffusion/Implant

- LPCVD: SiN, N+ poly Si, LPTEOS

- SiC, Ge, Si, SiGe epitaxy

- B, P, Al, N ion implantation

- Thermal oxidation (up to 1250 0°C)

- Implant activation (up to 2000 0°C)

CMP

- SiOx, SiN, Si

- Cu, barrier

Electroplating

- Cu TSV (high aspect ratio up to 1:15)

- Cu damascene, RDL

- Au, Ni, SnAg

Advanced Packaging

- Wafer-to-wafer fusion/hybrid bonding (with overlay accuracy 3σ <100 nm)

- Chip-to-wafer pick-and-place bonding

- Si-Si, Si-glass temporary bonding and debonding

- Mechanical dicing

- Si, glass backgrinding

Metrology and Inspection

- Micro and macro defect optical inspection

- Defect review SEM with EDX

- CDSEM, overlay metrology

- 3D optical profiler

- Surface roughness/morphology by 2D/3D AFM

- Dielectric and metal thickness metrology

- Confocal scanning acoustic microscopy

- Optical probe station