NSTIC – National Semiconductor Translation and Innovation Centre

Your R&D Translation Partner for Semiconductor Photonics Technologies

The National Semiconductor Translation and Innovation Centre (NSTIC) serves as Singapore’s strategic platform for semiconductor innovation, focused on advancing flat optics and photonics research.

By driving R&D translation, ecosystem collaboration, and talent development, NSTIC strengthens wafer fabrication capabilities and accelerates next-generation solutions that shape the future of electronics and data-driven technologies.

Pioneering Semiconductor Innovation at NSTIC

At NSTIC, we advance semiconductor research and development by translating breakthrough photonics technologies into industrial impact.

Our focus spans R&D fabrication, wafer-level prototyping, and the integration of next-generation materials for enhanced performance and scalability. By bridging research with real-world application, we accelerate the development of semiconductor innovations that power emerging technologies in data communication, imaging, and computing.

Anchored in Singapore’s deep-tech ecosystem, we collaborate closely with local and international partners to drive semiconductor innovation, reduce barriers to fabrication access, and enable faster product development cycles from lab to market.

R&D Fabrication

NSTIC advances semiconductor fabrication through research-driven development at the wafer scale, enabling translation of photonics innovation into tangible device prototypes. Our pilot line is equipped with industry-grade semiconductor tools—including lithography, etch, deposition, and metrology systems—designed to support high-precision flat optics fabrication and advanced photonic integration.

We specialise in developing new materials and process flows that feed into a growing intellectual property portfolio. Through wafer-level die-to-wafer (D2W) bonding techniques, we enable heterogeneous integration of high-performance photonic materials onto silicon platforms, unlocking new functionality across 8-inch and 12-inch wafers.

These R&D capabilities accelerate innovation pipelines for global partners seeking next-generation semiconductor solutions.

Wafer Fabrication in Singapore

Wafer fabrication is central to the semiconductor manufacturing process, converting high-purity silicon wafers into high value structured wafers used in integrated circuits and advanced devices. Each step demands precise control to achieve the quality required for high-performance microelectronics.

As demand for semiconductors intensifies across sectors like AI, communications, and mobility, Singapore plays a vital role in global supply chains through its robust infrastructure and advanced capabilities. NSTIC contributes to this momentum by developing next-generation wafer fabrication processes and material platforms that support R&D translation, from experimental builds to industry-ready photonic and electronic components.

Driving Technological Advancements in Semiconductor Fabrication and Research

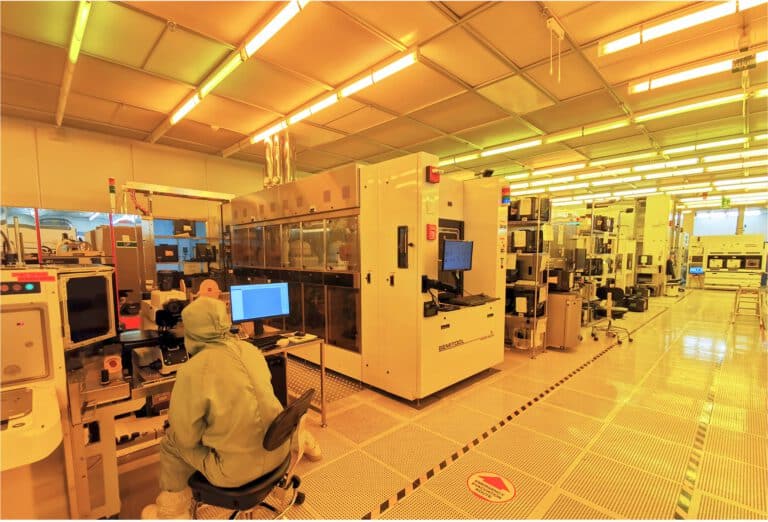

NSTIC offers a comprehensive semiconductor R&D infrastructure purpose-built to accelerate the translation of innovation into scalable technologies. Our facility houses a Class 10/100 cleanroom environment with capabilities for 8-inch and 12-inch silicon and glass wafer processing. Backed by a full suite of advanced fabrication tools—spanning lithography, dry/wet etching, thin film deposition, epitaxy, thermal processing, CMP, and electroplating—NSTIC supports end-to-end workflows from single-process runs to small volume device fabrication. This includes advanced integration technologies such as wafer-to-wafer bonding and chip-to-wafer placement. With high-resolution metrology and inspection systems integrated throughout, NSTIC enables rigorous process development for semiconductor photonics innovation and technology readiness.

New Wafer Fab in Singapore

As part of the NSTIC programme led by A*STAR, the national wafer fabrication facility is designed to strengthen Singapore’s position as a global semiconductor leader. It supports advanced R&D and wafer processing capabilities, enabling firms and researchers to transform chip-scale innovations into high-impact applicationsfor global deployment.

Partnering A*STAR Research Institutes and Universities for Cutting-Edge Semiconductor Solutions

NSTIC, hosted under A*STAR, bring together research institutes and universities to deliver national-level R&D translation for flat optics and silicon photonics. This collaboration enhances NSTIC’s ability to support industry and academic partners with access to advanced infrastructure, cleanroom capabilities, and integrated prototyping workflows.

Through this platform, companies can engage in the development of key semiconductor technologies—accelerating innovation cycles and improving scalability. By aligning with A*STAR’s research institutes and ecosystem partners, NSTIC plays a critical role in strengthening Singapore’s semiconductor value chain and advancing high-performance photonic and electronic solutions for global applications.

Why NSTIC is Leading Semiconductor R&D in Singapore and Beyond

NSTIC is uniquely positioned to support the semiconductor industry’s evolving demands through its focused approach to R&D translation, photonics innovation, and ecosystem development. Key differentiators include:

- Strategic Collaboration with A*STAR and universities: Anchored within Singapore’s research ecosystem to enable high-impact, translational R&D.

- Focus on Wafer-Level Fabrication: Equipped for 8″ and 12″ wafer processing to support advanced prototyping and process development.

- Specialisation in Flat Optics and Advanced Photonics: Drives the development of next-generation photonic devices for high-performance applications.

- Support for Ecosystem Collaboration: Facilitates joint research across academia, government, and industry.

- Commitment to Talent Development: Trains the next generation of semiconductor R&D professionals through hands-on engagement.

Our Services: Paving the Way for Semiconductor Innovation

NSTIC provides a suite of services to support semiconductor R&D translation, including access to cleanroom infrastructure, wafer-level prototyping, and small volume fabrication. Companies may also tap into processes and flows developed at NSTIC, which can be transferred to foundries for mass production. In addition, a portfolio of IPs in semiconductor fabrication, flat optics, and silicon photonics is available for industry licensing.

Explore our key offerings in:

Get in Touch with NSTIC Today

Connect with NSTIC to explore collaboration opportunities or learn more about how our semiconductor R&D capabilities can support your next innovation.